The Conventional welding Pipe Rtators has two types,bolt adjustment and lead screw adjustment.the bolt adjustable Roller center distance could be manually adjusted by reserved screw bolt, so as to suitable for various work piece diameter.Conventional rotators also can be supplied with a capacity from 5.000 kg up to 1000 tonnes.It can joint control with other equipments such as welding manipulator,welding machine, gantry type welding machine and so on.

Here Below is 500T Tank Turning Rolls specification:

| Model | CR-500 |

| Load capacity – Drive | 250 tons maximum |

| Load capacity – Idler | 250tons maximum |

| Load capacity – Set | 500 tons maximum |

| Rotation capacity | 500 tons maximum |

| Vessels diameter | Min. 1000mm ~ Max.8000mm |

| Rotation speed | 100~1000 mm/min VFD |

| Rotation power | 2*7.5kw with fan cooling |

| Roller wheels | PU (Polyurethane wheels) |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Welding Turning Roll /Pipe welding Rotators Description:

1. Our welding rollers pack One drive piece roller & one idler piece roller together as one set for sale.

2.Remote hand control, Radio hand control & Foot pedal control are all avaialble for this type Conventional Turning Roll

3.Top-class electronic components from Schneider to ensure long time using life.

4.Our tank tuning rolls’ drive rotation speed is in digital readout.

5.100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

6. If your single pipe/tank length is more than 8 meters, we suggest you choose one drive and two idler rollers to support work together.

Spare parts brand on our welding machine:

1. All our welding machine inverter is from Danfoss.

2. All our welding pipe rollers motor is from Invertek.

3. All our tank welding rolls electronic components is from Schneider.

4.CE certificates to European market and CO certificates with welding rotators to Middle East market.

Why Choose Wuxi Success pipe welding rotators:

1.Mainly used for big pipe, containers, boilers, pressure vessels, oil tank, wind tower and other cylinders assembly welding, blasting and painting.

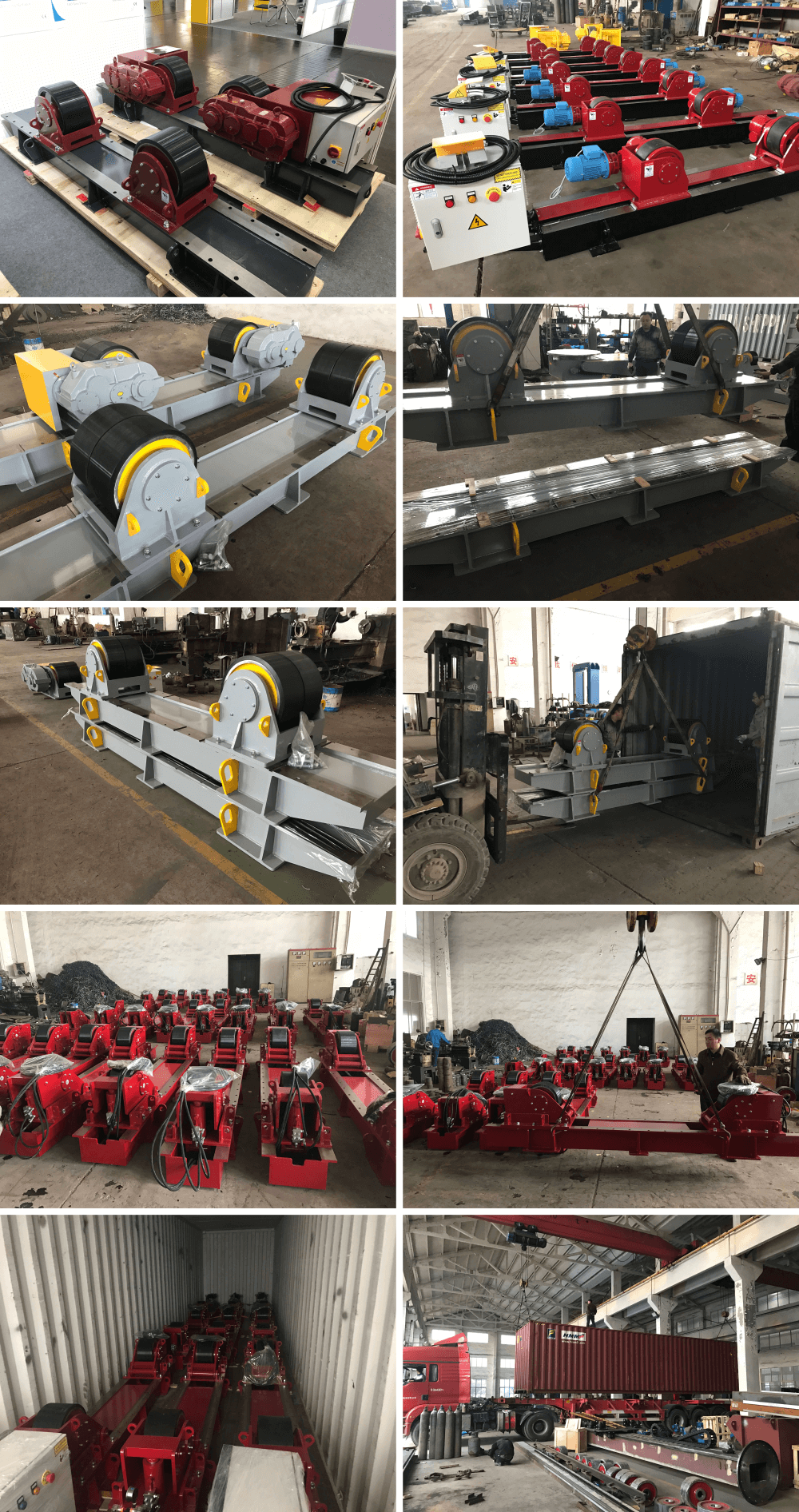

2.The rotator will be fully installed before package for delivery in wooden case.we also supply installation service.

3.One year warranty for welding rotator quality and free supported for spare parts.

4.We have strong delivery team, including the Sea freight and Air transportation. Door to door available.

5.Overseas agent is available in Italy and America market.

Our suggestion:

1.If your single pipe length more than 8 meter, we suggest you choose one drive roller and two idler rollers to support.

2.If your tank material is stainless steel,then please choose our PU wheels roller wheels.

3.If you want the foot pedal control , please advise me when you send us the inquiry.

4.Movable pipe welding rollers are also available.

5.We suggest you choose the welding column and boom together with the rollers for auto tank welding.

our related products name:

pipe welding rollers,pipe turning rolls,tank welding rotator,tank turning rolls,tank welding rollers,oil tank welding totator, pressure vessels welding ,self aligning welding rotator,fit up welding rollers,tank welding turning rolls,welding rotator for winder tower,tube turning rolls, wheel frame, roller frame for wind tower welding, conventional pipe welding roller stand, sand blasting rotator, painting rotator,welding positioner,welding positioner table,welding positioner chuck,pipe welding positioners,welding rotator with positioner,column and boom manipulator,small welding manipulator for pipe,Wind Tower Welding Manipulator.

Adjustable Welding Roller Beds Control System:

1. All Our Conventional welding Turning Rollers are with standard remote hand control box and foot pedal control.

2. Wireless / radio hand control are available for Tank Roller Welding Machine,but normally for heavy duty and long pipe / tanks.

Package:

1. If order one / two sets pipe rollers,then we will pack in wooden case for LCL shipping ,as well with installation details.

2. If the welding turning rollers order quantity enough for one whole containers,we will pack into containers directly.

1. Wuxi Success Machinery & Equipment CO.,LTD have exported welding turning rolls to more than 30 countries in the world. European & America stocks is available.

2. Here below some pipe welding turning rotator working pictures are all from our clients feedback from their work site.

Australia 30T Lead Screw Conventional Pipe Welding Turning Rolls.

ITALY 40T and 60T Bolt Adjustment Tube Welding Rotators with PU wheels.

AMERICA 100T Bolt Adjustment CONVENTIONAL PIPE WELDING TURNING ROLLERS WORKING FOR HEAVY VESSELS.