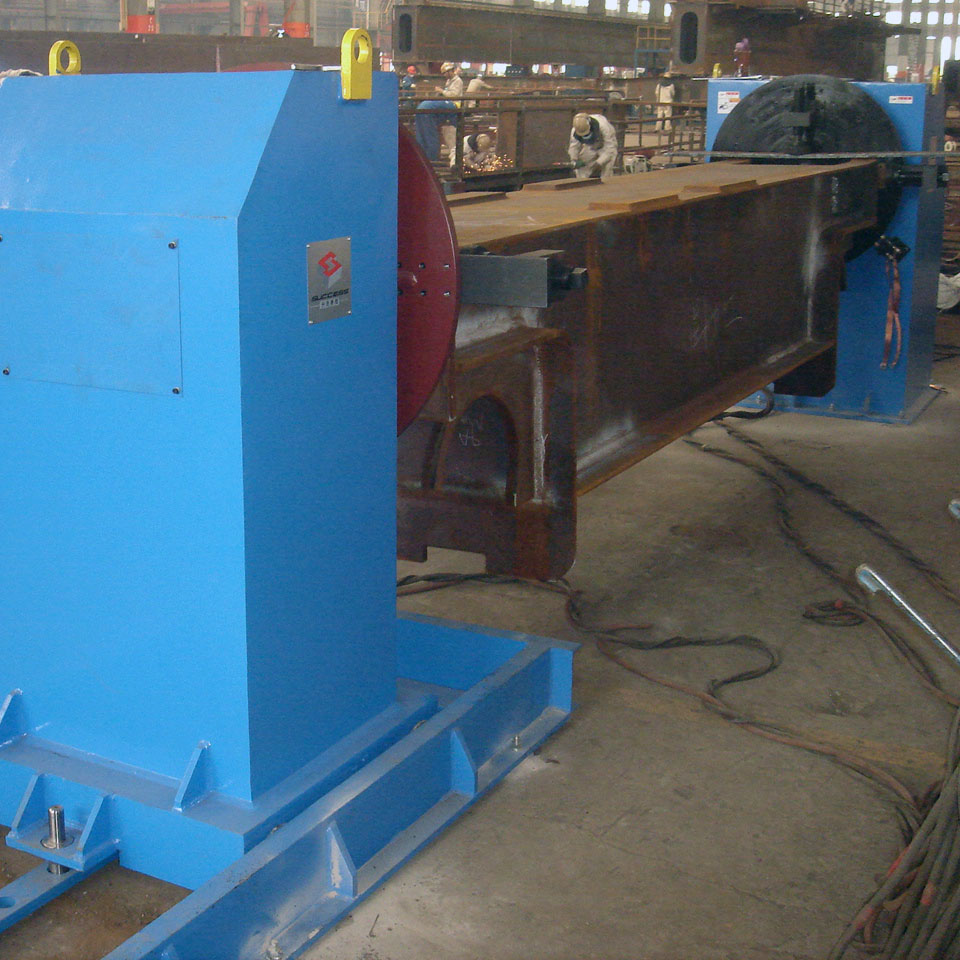

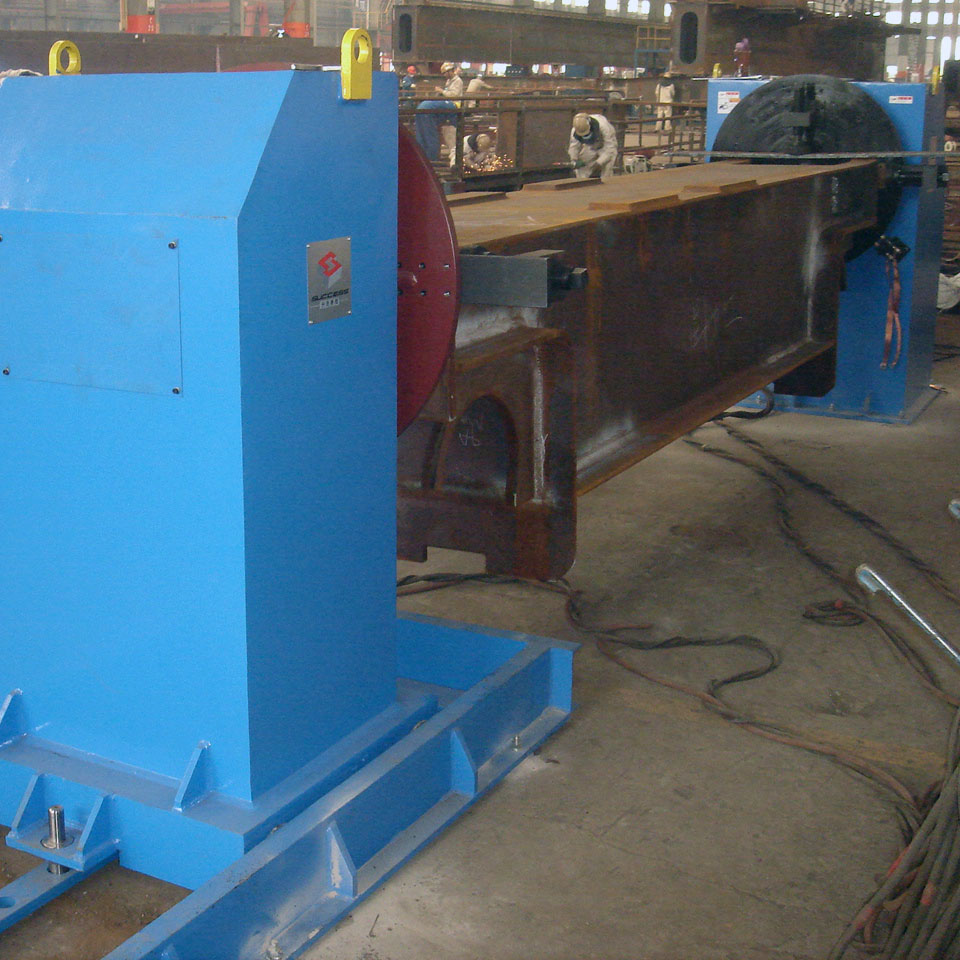

2017 China New Design Anti Drift Welding Rotator - 200T Conventional welding rotator – Wuxi Success Detail:

The bolt adjustable welding Roller center distance could be manually adjusted by reserved screw bolt, so as to suitable for various work piece diameter. and conventional welding rotator can be supplied with a capacity from 5000 kg up to 1000 Tons.It is produced according with mechanical standard JB/T 9187-1999.and it can joint control with other equipments such as welding manipulator,welding machine, gantry type welding machine and so on.

Here Below is 200T Bolt Adjustable Tank Turning Roll Beds With PU Wheels specification:

| Model | CR-200 |

| Load capacity – Drive | 100 tons maximum |

| Load capacity – Idler | 100tons maximum |

| Load capacity – Set | 200 tons maximum |

| Rotation capacity | 200 tons maximum |

| Vessels diameter | Min. 800mm ~ Max.5000mm |

| Rotation speed | 100~1000 mm/min VFD |

| Rotation power | 2*4kw with fan cooling |

| Roller wheels | PU (Polyurethane wheels) |

| Control way | Remote hand control + Foot pedal |

| Input Voltage | 110V ~ 575V Single/3 Phase 50/60Hz |

| Certificate | CE approval |

Bolt Adjustable Pressure Vessel Welding Rotators Description:

1. Our welding rollers pack One drive piece roller & one idler piece roller together as one set for sale.

2.Remote hand control, Radio hand control & Foot pedal control are all avaialble for water tank/cylinder pipe welding rotator.

3.Top-class electronic components from Schneider to ensure long time using life.

4.Depends on different application, the roller surface has three types,PU/RUBBER/STEEL WHEEL

5.Power roller of the welding rotator is driven by double motor. Reducer adopts cycloidal planetary gear reducer or worm reduction gear mode.

6. 100% new from original manufacturer – WUXI SUCCESS MACHINERY EQUIPMENT CO., LTD.

Tank Turning Roller Machine Advantages :

1. All our tank body welding roller inverter is from Danfoss.

2. All our adjustable welding rotator motor is from Invertek.

3. All our pipe welding roller stand electronic components is from Schneider.

4.CE certificates to European market and CO certificates with welding rotators to Middle East market.

5.The conventional welding rotator is mainly used for the welding,polishing,painting and assembly of cylindrical roller shell. It also can assembling or using together with other tooling for the cone inequality diameter rotary.

Pipe Welding Rolls From Wuxi Success Usage:

1. Medium range series has been engineered for the effective positioning of long cylindrical work-pieces.

2. Oil tanks, pressure vessels, and pipe are applications that utilize turning rolls.

3. Long objects that are not cylindrical may be adapted with the aid of custom designed support rings.

4. We design incorporates overload discs on each wheel that prevent excessive loads from damaging the tires.

More Questions Customers May Concerned On Our Pressure Vessels Welding Pipe Turning Rolls:

Q : What about the transportion?

A : 1. Fully packaged in wooden case to anti damage during the transportational process .

2. Usually we take seaway ,cause its more convenient and cheaper for big machine.

3. Door to door delivery service is also available.

Q : What is your warranty and after sale service ?

A : 1. All our equipments with One Year Warranty time , fully test at our work shop before delivery.

2. If you have any questions on the installation , you will get our engineers respond within 24 hours.

Q. Quality Process Control:

A : All the machines are done testing before shipment. A 30min trial working is executed to guarantee the machine be faultless.

Product detail pictures:

Related Product Guide:

The Purpose of Welding Positioners in the Manufacturing Industry

Sheet Metal Fabricators – Hot Tips For Welding Flat Rolled Steel

Our well-equipped facilities and exceptional good quality manage throughout all stages of production enables us to guarantee total shopper satisfaction for 2017 China New Design Anti Drift Welding Rotator - 200T Conventional welding rotator – Wuxi Success, The product will supply to all over the world, such as: Rotterdam, Liberia, Brunei, What is good price? We provide customers with factory price. In the premise of good quality, efficiency will have to be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products and solutions in time. Sincerely hope we could have long term business relationship.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!

-

Chinese Professional Rotating-automatic Welding...

View Detail -

Cheap price Tungsten Carbide Roller - 2000kg H...

View Detail -

Hot sale 180 Degree Rotation Cnc Router - 2000...

View Detail -

Manufacturer of Rotating Part Flange - 1000kg ...

View Detail -

Good Quality Welding Platform - 1000kg Height ...

View Detail -

Cheapest Factory Rotary Pipe Welding Turning Ta...

View Detail